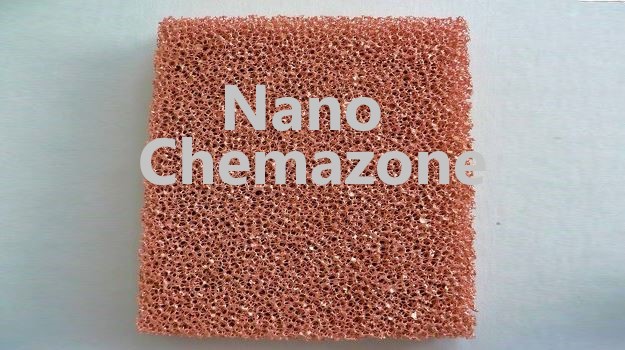

Premium Grade Copper Metal Foams

₹0.00

Product: Copper Foam (Cu Foam, Purity: 99.9%, 50PPI/1mm)

Copper Metal Foams

| Stock No. | NCZFF102 |

| PPI | 10 to 110, customization is also possible |

| Bulk Density | 0.80-0.85 g/cc |

| Purity | ≥99.9% |

| Porosity | ≥70% , customization is also possible |

| Dimension | 500 mm X 500 mm, customization is also possible |

| Thickness | 1mm to 25mm, customization is also possible |

Physical Characteristics of Cu Foam

| Compression Strength | 131 psi |

| Tensile Strength | 1000 psi |

| Shear Strength | 190 psi |

| Modulus of Elasticity (Compression) | 107 kpsi |

| Modulus of Elasticity (Tension) | 14.6 × 103 psi |

| Shear Modulus | 40.9 kpsi |

| Vickers Hardness | 35 |

| Specific Heat | 0.385 J/g-°C |

| Bulk Thermal Conductivity | 10.1 W/m-°C |

| Coefficient of Thermal Expansion | 1.7 × 10-5 m/m–°C (0-100°C) |

| Bulk Resistivity | 2.56× 10-5 ohm – in |

| Melting Point | 1080 °C |

Copper foam available as open cell and closed cell. Please ask for customization while ordering.

Note: For pricing & ordering information, please contact us at sales@nanochemazone.com

Please contact us for quotes on Larger Quantities & Customization. E-mail: contact@nanochemazone.com

Customization:

If you are planning to order large quantities for your industrial and academic needs, please note that customization of parameters (such as size, length, purity, functionalities, etc.) are available upon request.

Related products

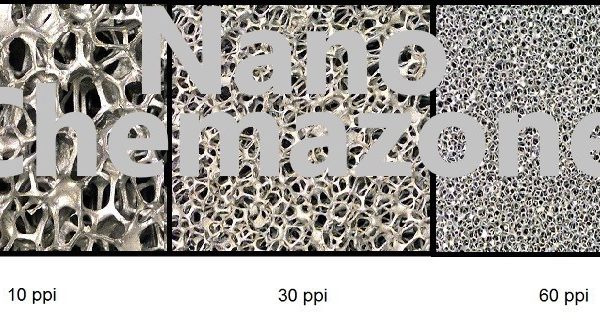

Aluminium Foam Panel

Aluminium Metal Foams Panel

Aluminium Metal Foams

| Product | Aluminium Foam Panel |

| Stock No. | NCZFF113 |

| CAS No. | 7429-90-5 |

| Purity | 99.9% |

| Cell Type | Closed Cell as well as Open Cell, customization is available |

| Density | 0.35g /cm³~ 0.7g /cm³ |

| Tensile Strength | 1.3~2.0 Mpa |

| Compressive Strength | 1.5~2.0 Mpa |

| Thermal Conductivity | 0.268 W/m.K |

| Melting Point | 780 °C |

| Shape | Foam Panel |

| Number of pores/inch (PPI) | 10-100 PPI, customization is possible on demand |

| Thickness | 1 mm – 250 mm, customization is possible on demand |

| Available Sizes | 100 x 100 mm, 500 x 500 mm, 600 x 600 mm, 1000 x 500 mm, 1200 x 600 mm, 2000 x 800 mm, Size customization is possible on demand |

| Storage Conditions | Stored in a cool and dry place, away from the fire, Heat source |

Aluminium Metal Foam Open Cell or Closed Cell, Both are available (Ask for Size Customization)

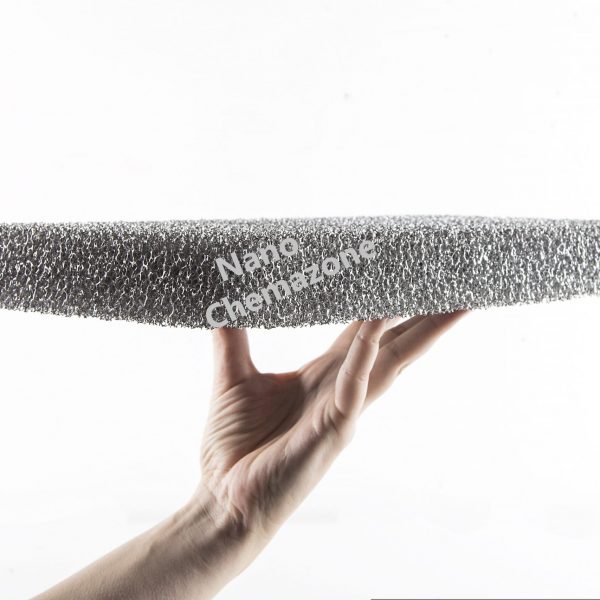

Aluminum Metal Foam

Aluminium Metal Foams

Product: Aluminium Metal Foam (Closed Cell or Open Cell, 2-11 mm)

| Stock No. | NCZFF108 |

| Density | 0.1 to 0.35 g/cm³ |

| Pore Size | 2-11 mm, 5 mm (Closed Cell as well as Open Cell) |

| Porosity | 60-90%, customization is also possible |

| Compressive Strength | 44 Mpa |

| Blending Strength | 27 Mpa |

| Acoustic Absorptive | 0.48 |

| Foam Size | 100 x 100 x 5 mm, customization is also possible |

Physical Characteristics Aluminium Metal Foam

| Heat Resistivity | 660 °C |

| Acoustic Frequency | Between 125 and 2000 HZ |

| Noise Reduction Coefficient | >0.4 |

| Thermal Insulation Properties | About 1 / 400 of metal Aluminium |

| Electromagnetic Wave Frequency | Between 2.6 and 18 GHZ |

| Electromagnetic Shielding Property | Up to 60 – 90 dB |

| Resistivity | 100 Times Over Metal Aluminium |

Aluminium Metal Foam Open Cell or Closed Cell, Both are Available (Ask for Customization)

Copper Foil Sheets

| Materials | Copper Foil Sheets |

| Stock No. | NCZ-F-0011 |

| CAS | 7440-50-8 |

| Purity | ≥99.8% |

| APS | <20 µm, customization is available |

| Surface density | 175-181 g/m² |

| Tensile strength | ≥30 (25 °C) Kg/mm² |

| Extensibility | ≥8% |

| Roughness Rz | ≤3.0 μm |

| Thickness Tolerance | -0, 3 |

| Width Tolerance | ±1 |

| Tolerance Oxidation Susceptibility | 160°C/10 min.no oxidation |

| Polished | Single/Both Side Polished |

| Appearance Quality | No oxidation, smooth and no concave-convex |

EVA Foam (Ethylene Vinyl Acetate and blended copolymers)

Product: EVA Foam Sheet (Ethylene Vinyl Acetate and blended copolymers)

CAS No.: 24937-78-8

Stock Number: NCZFF111

| Product Name | EVA Foam Sheet |

| Purity | >99.9% |

| Density | 30 kg/m3 |

| Surface Hardness | 40 °C |

| Tear Strength | 0.35 N/mm m² |

| Tensile Strength | 780 Kpa |

| Elongation at break | 100 % |

| Compression Strength | 78 Kpa |

| Compression deformation | 25 % |

| Size Change Rate | 0.8 % |

| Rebound Rate | 26.00 % |

| Elongation | 130 % |

| Service Temperature | -30 to 180 °F |

| Thermal Conductivity | 0.038 W/mK |

| Adhesive Thickness | 0.15 mm |

| Adhesive Weight | 80 g/m³ |

| Adhesion | 18 N/25 mm |

| Application | 10 °C min |

| Service | -50~ 100 °C |

| Short peak | 120 °C |

| Storage Life | 3 year |

Ask for customization while ordering

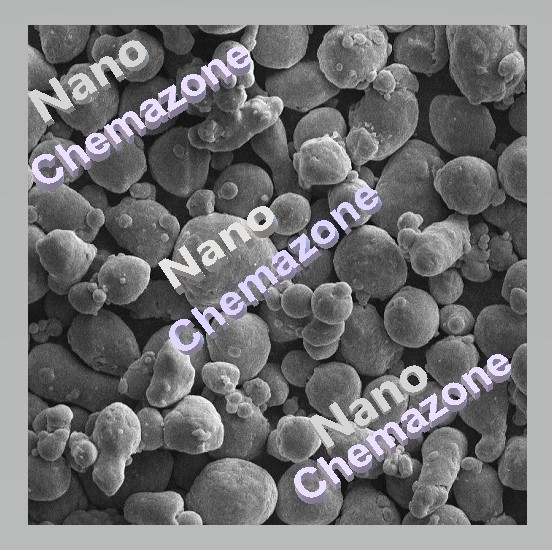

Open Cell Copper Foam Heat Exchanger

Open Cell Copper Foam Heat Exchanger

Copper Metal Foam open cell

| Stock No. | NCZFF105 |

| PPI | 10 to 110 PPI, customization is also possible |

| Bulk Density | 0.80-0.85 g/cc |

| Purity | ≥99.9% |

| Porosity | ≥70%, customization is also possible |

| Dimension | 500 mm X 500 mm, customization is also possible |

| Thickness | 1 mm to 25 mm, customization is also possible |

| Compression Strength | 131 psi |

| Tensile Strength | 1000 psi |

| Shear Strength | 190 psi |

| Modulus of Elasticity (Compression) | 107 kpsi |

| Modulus of Elasticity (Tension) | 14.6 × 103 psi |

| Shear Modulus | 40.9 kpsi |

| Vickers Hardness | 35 |

| Specific Heat | 0.385 J/g-°C |

| Bulk Thermal Conductivity | 10.1 W/m-°C |

| Coefficient of Thermal Expansion | 1.7 × 10-5 m/m–°C (0-100°C) |

| Bulk Resistivity | 2.56× 10-5 ohm – in |

| Melting Point | 1080 °C |

Ask for customization while ordering

Palladium Metal Foil

| Materials | Palladium Metal Foil |

| Stock No. | NCZ-F-0016 |

| CAS | 7440-05-3 |

| Purity | ≥ 99.9% |

| Thickness | 12 μm, customization is possible |

| Width | 30~500 mm, customization is possible |

| Surface density | 12.023 g/cm3 |

| Melting Point | 1554 °C |

| Boiling Point | 2963 °C |

| Joint | 1pcs/roll |

| Polished | One / Both Side Polished |

| Polished | One Side Coarse |

Polyethylene Foam

Product: Polyethylene Foam (Closed Cell, Purity: >99.9%)

CAS: 9002-88-4| Product Name | Polyethylene Foam |

| Product Code | NCZFF110 |

| Purity | >99.9% |

| Density | 1.2 (LB/Cubic Ft. |

| Color | White |

| Cell Count | 18 (cells/inch) |

COMPRESSIVE STRENGTH

| 25% | 7 (LB/In. Sq.) |

| 50% | 12 (LB/In. Sq.) |

COMPRESSION SET

| 2 hours | 30 % |

| 24 hours | 24 % |

| Compression Creep | 5 % |

| Water Absorption | 0.06 LB/Sq. Ft. |

| Thermal Stability | <2 % |

| Service Temperature | -30 to 180 °F |

| Contains Fire Retardant Additives | No |

Polyethylene Foam Closed Cell as well as Open Cell (Ask for customization while ordering)

Reticulated Vitreous Carbon Foam

RVC foam density/Open Cell RVC Foam

Reticulated Vitreous Carbon Foam (RVC) / Glassy Carbon Foam

| Materials | Reticulated Vitreous Carbon Foam |

| Stock No | NCZFF112 |

| CAS | 7440-44-0 |

| Purity | 99.9% |

| Thickness | 2 mm-50 mm (Customizable) |

| PPI | 10-110 PPI (Customizable) |

| Size | 50 x 50 mm, 100 x 100 mm, 200 x 200 mm (Ask for Size customization) |

RVC foam density is customizable on request while ordering. reticulated vitreous carbon foam reticulated foam.

Application: Reticulated Vitreous Carbon Foam for Electrochemistry Electrodes, High Surface Area, Temperature Stability, etc. RVC foam reticulated foam

12.7 × 10-2 ohm • in of RVC foam

5 mm, customization is also possible in RVC foam

Product: Carbon Foam (Purity: 99.9%, Thickness: 5mm) reticulated vitreous carbon foam, RVC foam, Reticulated foam