Boron Trioxide Powder

₹0.00

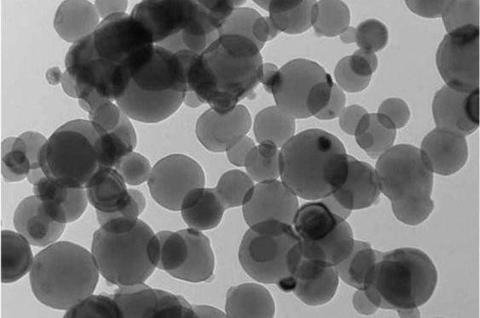

Boron Trioxide Powder

Product Name: Boron Trioxide Powder

| Product | Boron Trioxide Powder |

| CAS No. | 1303-86-2 |

| Appearance | White Powder |

| Purity | 99.9% |

| APS | 75um (Can be customized) |

| Ingredient | B2O3 |

| Product Code | NCZ-NSC400-/20 |

Boron trioxide Powder Description :

Boron trioxide Powder is one of the oxides of boron. It is a white, glassy solid with the formula B2O3.

It is almost always found as the vitreous (amorphous) form; however, it can be crystallized after extensive annealing (that is, under prolonged heat).

Glassy boron oxide (g-B2O3) is thought to be composed of boroxol rings which are six-membered rings composed of alternating 3-coordinate boron and 2-coordinate oxygen.

Because of the difficulty of building disordered models at the correct density with many boroxol rings, this view was initially controversial, but such models have recently been constructed and exhibit properties in excellent agreement with the experiment.

It is now recognized, from experimental and theoretical studies, that the fraction of boron atoms belonging to boroxol rings in glassy B2O3 is somewhere between 0.73 and 0.83, with 0.75 correspondings to a 1:1 ratio between the ring and non-ring units.

The number of boroxol rings decays in the liquid state with increasing temperature.

The crystalline form (α-B2O3) (see structure in the infobox) is exclusively composed of BO3 triangles. This trigonal, quartz-like network undergoes a coesite-like transformation to monoclinic β-B2O3 at several gigapascals (9.5 GPa).

Boron trioxide is produced by treating borax with sulfuric acid in a fusion furnace.

At temperatures above 750 °C, the molten boron oxide layer separates from sodium sulfate. It is then decanted, cooled, and obtained in 96–97% purity.

Another method is heating boric acid above ~300 °C. Boric acid will initially decompose into steam, (H2O(g)) and metaboric acid (HBO2) at around 170 °C and further heating above 300 °C will produce more steam and diboron trioxide. The reactions are:

H3BO3 → HBO2 + H2O

2 HBO2 → B2O3 + H2O

Boric acid goes to anhydrous microcrystalline B2O3 in a heated fluidized bed. A carefully controlled heating rate avoids gumming as water evolves.

Molten boron oxide attacks silicates. Internally graphitized tubes via acetylene thermal decomposition are passivated.

Crystallization of molten α-B2O3 at ambient pressure is strongly kinetically disfavored (compare liquid and crystal densities).

The threshold conditions for the crystallization of the amorphous solid are 10 kbar and ~200 °C.

Its proposed crystal structure in enantiomorphic space groups has been revised to enantiomorphic space groups P3121(#152); P3221(#154) (e.g., α-quartz).

Boron oxide will also form when diborane (B2H6) reacts with oxygen in the air or trace amounts of moisture.

Boron trioxide Powder Related Information

Storage Conditions:

Airtight sealed, avoid light, and keep dry at room temperature.

Please contact us for customization and price inquiry

Email: contact@nanochemazone.com

Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.

Note: For pricing & ordering information, please contact us at sales@nanochemazone.com

Please contact us for quotes on Larger Quantities & Customization. E-mail: contact@nanochemazone.com

Customization:

You must be logged in to post a review.

Related products

Ferro Titanium Carbide Powder

Product Name: Ferro Titanium Carbide Powder

| Product | Ferro Titanium Carbide Powder |

| Colour | Gray Powder |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | FeTiC |

| Product Code | NCZ-C-102/20 |

| CAS Number | 12604-56-7 |

Application of Ferro Titanium carbide powder:

In the present study, Fe-based hardfacing coating reinforced by TiC particles was obtained by manual shielded metal arc welding (SMAW) in which H08A bare electrode was coated with fluxes, to which different measures of ferrotitanium, rutile, graphite, calcium carbonate, and calcium fluoride had been added.

The microstructure and wear properties of the hardfacing coating were studied through scanning electron microscopy (SEM), transmission electron microscopy (TEM), an X-ray diffractometer (XRD), and a wear test.

The results indicate that TiC particles are produced by a direct metallurgical reaction between ferrotitanium and graphite during welding.

TiC particles are uniformly dispersed in the matrix of lath martensite and retained austenite with particle sizes in the range of 3–5 μm. Fe-based hardfacing coating reinforced by TiC particles is found to possess better wear resistance and a lower coefficient of friction than that of the AISI 1045 steel substrate.

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Ferrochrome Nitride Powder

Ferrochrome Nitride Powder

Product Name: Ferrochrome Nitride Powder

| Product | Ferrochrome Nitride Powder |

| Colour | Black Powder |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | FeCrN |

| Product Code | NCZ-CN-151/20 |

| CAS Number | 7439-89-6, / 24094-93-7 |

Ferrochrome Nitride Powder Description:

Ferrochrome nitride is widely used in electric furnace and oxygen converter smelting nitrogen steel. Nitrogen is an element of austenite formation, It is used as a component to add chromium manganese and chromium manganese nickel stainless steel to replace the shortage of nickel.Ferrochrome Nitride Powder Application:

Ferrochrome, or ferrochromium (FeCr) is a type of ferroalloy, that is, an alloy of chromium and iron, generally containing 50 to 70% chromium by weight.

Ferrochrome is produced by electric arc carbothermic reduction of chromite. Most of the global output is produced in and India, which have large domestic chromite resources. Increasing amounts are coming from Russia and China.

Production of steel, especially that of stainless steel with a chromium content of 10 to 20%, is the largest consumer and the main application of ferrochrome.

Ferrochrome production is essentially a carbothermic reduction operation taking place at high temperatures. Chromium ore (an oxide of Cr and Fe) is reduced by coal and coke to form the iron-chromium alloy.

The heat for this reaction can come from several forms, but typically from the electric arc formed between the tips of electrodes at the bottom of the furnace and the furnace hearth.

This arc creates temperatures of about 2,800 °C (5,070 °F). In the process of smelting, huge amounts of electricity are consumed, making production very expensive in countries where power costs are high.

The tapping of the material from the furnace takes place intermittently. When enough smelted ferrochrome has accumulated in the furnace hearth.

The tap hole is drilled open and a stream of molten metal and slag rushes down a trough into a chill or ladle. Ferrochrome solidifies in large castings that are crushed for sale or further processed.

Ferrochrome is generally classified by the amount of carbon and chrome it contains.

The vast majority of FeCr produced is "charge chrome" from South Africa, with high carbon being the second largest segment followed by the smaller sectors of low carbon and intermediate carbon material.

Ferrochrome Nitride Powder Related Information

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Ferrochrome Nitride Powder

| Product | Ferrochrome Nitride Powder |

| Colour | Black |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | FeCrN |

| Product Code | NCZ-CN-151/20 |

| CAS Number | 7439-89-6, / 24094-93-7 |

- Widely used in stainless steel, heat resistant steel, corrosion-resistant steel, alloy steel, and other special steel smelting production

- Used in steelmaking industrial, casting foundry

Iron Boride Powder

Product Name: Iron Boride Powder

| MF: | Tr-FeB |

| Chemical Name | Iron Boride Powder |

| Color | Grey Powder |

| EINECS Number: | 234-489-9 |

| Purity: | 99.9% |

| Density | ~7 g/cm3 |

| Product Number: | NCZ-NIB-112/20 |

| Cas Number: | 12006-84-8 |

Iron Boride Powder Description

Iron Boride Powder is often used to improve abrasion resistance, corrosion resistance, wear resistance, and oxidation resistance. It is used in oil and gas refinery, chemical extraction, automotive agricultural, stamping, textile extrusion, and injection molding industries. Iron-based coatings recently gained attention for their mechanical, frictional, and corrosion-resistant properties. As compared to the ceramic or cermet type of materials people have used before, iron-based materials are relatively inexpensive, less strategic, and can be produced economically by various thermal methods with ease of fabrication and machining.

Iron Boride Powder Related Information

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Manganese Nitride Powder

Manganese Nitride Powder

Product Name: Manganese Nitride Powder

| Product | Manganese Nitride Powder |

| Colour | Dark Gray |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | MnN |

| Product Code | NCZ-CN-148/20 |

| CAS Number | 7439-96-5 |

Manganese Nitride Powder Description:

Manganese Nitride Powder is generally immediately available in most volumes. High purity, submicron and nanopowder forms may be considered. Our factory produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade

Manganese Nitride in Briquettes, as a kind of Nitrogen and manganese alloy additive, its characteristics are: high content of main elements, low content of harmful impurities, Nitrogen utilization is to be improved after add melt. We adopt the continuous nitride process with unique intellectual property rights in mass production, which has stable quality and uniform nitrogen

Manganese Nitride Powder Application:

- Used for production of special alloy steel, high strength steel, stainless steel, heat-resistant steel products

2. Application in the field of high nitrogen steel smelting

- Used as the steel-making additive and endow many excellent performances to steel grade such as strength, toughness, creep resistance, etc.

- Specialty demonstrated its good market prospects in large diameter steel pipe of transmitting oil and gas strength steel in shipbuilding and automotive.

Basic information of Manganese Nitride Powder

Manganese (atomic symbol: Mn, atomic number: 25) is a Block D, Group 7, Period 4 element with an atomic weight of 54.938045.

In its elemental form, manganese has a silvery metallic appearance.

It is a paramagnetic metal that oxidizes easily in addition to being very hard and brittle.

Manganese is found as a free element in nature and also in the minerals pyrolusite, braunite, psilomelane, and rhodochrosite.

Nitrogen is a Block P, Group 15, Period 2 element.

Nitrogen is an odorless, tasteless, colorless, and mostly inert gas.

It is the seventh most abundant element in the universe, and it constitutes 78.09% (by volume) of Earth’s atmosphere.

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Niobium Boride Powder

Niobium Boride Powder

Product Name: Niobium Boride Powder

| MF | NbB |

| Chemical Name | Niobium Boride Powder |

| EINECS | 235-723-2 |

| Purity | 99.9% |

| Molecular weight | 103.72 |

| Product Number | NCZ-SC-112/20 |

| Cas Number | 12007-29-3 |

| Density | 7.39g/ml |

Niobium Boride Powder

Niobium boride Powders having NbB, NbB2, and Nb3B4 phases in various amounts and single-phase NbB powders were successfully synthesized by using powder metallurgy methods from related metal oxide raw materials in the presence of a strong reducing agent. Nb2O5, B2O3, and Mg powder blends were milled at room temperature by a high-energy ball mill for a different time. Subsequently, an undesired MgO phase was removed from the milled powders by HCl leaching to constitute NbB–NbB2–Nb3B4 as final products, and they were subjected to an annealing process at 1500 °C for 4 h to observe probable boride transformation. Characterization was carried out by XRD, DSC, PSA, SEM/EDX, TEM, and VSM.

The effects of milling time (up to 9 h) on the formation, microstructure, and thermal behavior of the final products were investigated. The reduction reaction took place after milling stoichiometric powder blends for 2 h. Nano-sized NbB–NbB2–Nb3B4 powders in high purity were obtained in the absence of any secondary phase and any impurity via mechanochemistry by milling for 5 h and leaching with 4 mol/L HCl. After annealing, pure and nano-sized NbB–NbB2–Nb3B4 powders transformed to a single NbB phase without leaving behind NbB2 and Nb3B4 phases.

RELATED INFORMATION Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Tungsten Carbide Powder

Tungsten Carbide Powder

Product Name: Tungsten Carbide Powder

| Product | Tungsten Carbide Powder |

| Colour | Grey |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | WC |

| Product Code | NCZ-C-109/20 |

| CAS Number | 12070-12-1 |

Brief Description of WC Tungsten Carbide Powder

Tungsten carbide powder (chemical formula: WC ) is a chemical compound (specifically, a carbide ) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine Gray powder, but it can be pressed and formed into shapes for use in industrial machinery, cutting tools, abrasives, armor-piercing rounds, other tools and instruments, and jewelry. Physical Properties of WC Tungsten Carbide Powder Tungsten carbide has a high melting point at 2,870 °C (5,200 °F), a boiling point of 6,000 °C (10,830 °F) when under a pressure equivalent to 1 standard atmosphere (100 kPa), the thermal conductivity of 110 W·m−1·K−1, and a coefficient of thermal expansion of 5.5 µm·m−1·K−1. Tungsten carbide is extremely hard, ranking about 9 on Mohs scale, and with a Vickers number of around 2600. It has Young’s modulus of approximately 530–700 GPa, a bulk modulus of 630–655 GPa, and a shear modulus of 274 GPa. It has an ultimate tensile strength of 344 MPa, the ultimate compression strength of about 2.7 GPa and a Poisson’s ratio of 0.31. Chemical Properties of WC Tungsten Carbide Powder There are two well-characterized compounds of tungsten and carbon, WC and tungsten semi abide, W2C. Both compounds may be present in coatings and the proportions can depend on the coating method. At high temperatures, WC decomposes to tungsten and carbon and this can occur during high-temperature thermal spray, e.g., in high-velocity oxygen fuel (HVOF) and high energy plasma (HEP) methods.Application of WC Tungsten Carbide Powder

1 Used for Producing high capability nano-crystalline or superfine horniness alloy, hard-face abrasion-resistant spraying and petrochemical cracking catalyst;- Used for chipless forming tools; Cutting tools; Mining tolls; Nano-composites (for enhanced hardness, strength, and wear resistance);

- Used for erosion-resistant coatings; wear-resistance coatings; Corrosion-resistant coatings; Wear-resistant parts

- To produce hard carbide.

Zirconium Carbide Powder

Zirconium Carbide Powder

Product Name: Zirconium Carbide Powder

| Product | Zirconium Carbide Powder |

| Colour | Black |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | ZrC |

| Product Code | NCZ-C-110/20 |

| CAS Number | 12070-14-3 |

Reviews

There are no reviews yet.