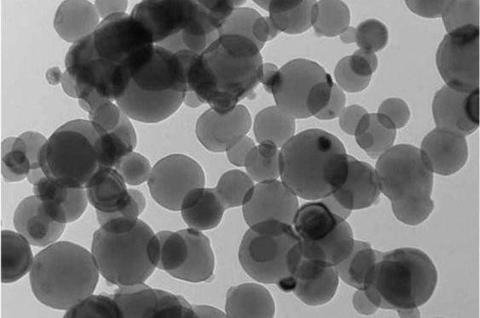

Iron Boride Powder

₹0.00

Product Name: Iron Boride Powder

| MF: | Tr-FeB |

| Chemical Name | Iron Boride Powder |

| Color | Grey Powder |

| EINECS Number: | 234-489-9 |

| Purity: | 99.9% |

| Density | ~7 g/cm3 |

| Product Number: | NCZ-NIB-112/20 |

| Cas Number: | 12006-84-8 |

RELATED INFORMATION

Boriding is often used to improve abrasion resistance, corrosion resistance, wear resistance, and oxidation resistance. It is used in oil and gas refinery, chemical extraction, automotive agricultural, stamping, textile extrusion, and injection molding industries. Iron-based coatings recently gained attention for their mechanical, frictional, and corrosion-resistant properties. As compared to the ceramic or cermet type of materials people have used before, iron-based materials are relatively inexpensive, less strategic, and can be produced economically by various thermal methods with ease of fabrication and machining.

Please email us for the customization.

Email: contact@nanochemazone.com

Please contact us for customization and price inquiry

Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.

Note: For pricing & ordering information, please contact us at sales@nanochemazone.com

Please contact us for quotes on Larger Quantities & Customization. E-mail: contact@nanochemazone.com

Customization:

If you are planning to order large quantities for your industrial and academic needs, please note that customization of parameters (such as size, length, purity, functionalities, etc.) are available upon request.

You must be logged in to post a review.

Related products

Aluminum Powder

Aluminum Powder

Product Name: Al Powder

| Product | Al Powder |

| CAS No. | 7429-90-5 |

| Appearance | Grey |

| Purity | 99.9% |

| APS | 1 – 5 Micron (Can be customized) |

| Ingredient | Al+3 |

| Product Code | NCZ-NSC-163/20 |

Description of Al (Aluminum Powder)

| 3D printing metal Powder Powder metallurgy, injection molding, spray painting, etc. |

Al Powder Related Information

Storage Conditions:

Airtight sealed, avoid light, and keep dry at room temperature. Please email us for the customization. Email: contact@nanochemazone.comChromium Diboride Powder

Chromium Diboride Powder

| MF: | CrB2 |

| Chemical Name |

Chromium Diboride Powder |

| Appearance | Silver, Ceramic Material |

| EINECS | 234-499-3 |

| Purity: | 99.9% |

| Density: | 5.20 g/cm3 |

| Product Number: | NCZ-NCD-117/20 |

| Cas Number: | 12007-16-8 |

Chromium Diboride Powder

Chromium Diboride Powder

Product Name: Chromium Diboride Powder

| MF: | CrB2 |

| Chemical Name |

Chromium Diboride Powder |

| Appearance | silver, ceramic material |

| EINECS | 234-499-3 |

| Purity: | 99.9% |

| Density: | 5.20 g/cm3 |

| Product Number: | NCZ-NCD-117/20 |

| Cas Number: | 12007-16-8 |

Ferrochrome Nitride Powder

Ferrochrome Nitride Powder

Product Name: Ferrochrome Nitride Powder

| Product | Ferrochrome Nitride Powder |

| Colour | Black Powder |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | FeCrN |

| Product Code | NCZ-CN-151/20 |

| CAS Number | 7439-89-6, / 24094-93-7 |

Ferrochrome Nitride Powder Description:

Ferrochrome nitride is widely used in electric furnace and oxygen converter smelting nitrogen steel. Nitrogen is an element of austenite formation, It is used as a component to add chromium manganese and chromium manganese nickel stainless steel to replace the shortage of nickel.Ferrochrome Nitride Powder Application:

Ferrochrome, or ferrochromium (FeCr) is a type of ferroalloy, that is, an alloy of chromium and iron, generally containing 50 to 70% chromium by weight.

Ferrochrome is produced by electric arc carbothermic reduction of chromite. Most of the global output is produced in and India, which have large domestic chromite resources. Increasing amounts are coming from Russia and China.

Production of steel, especially that of stainless steel with a chromium content of 10 to 20%, is the largest consumer and the main application of ferrochrome.

Ferrochrome production is essentially a carbothermic reduction operation taking place at high temperatures. Chromium ore (an oxide of Cr and Fe) is reduced by coal and coke to form the iron-chromium alloy.

The heat for this reaction can come from several forms, but typically from the electric arc formed between the tips of electrodes at the bottom of the furnace and the furnace hearth.

This arc creates temperatures of about 2,800 °C (5,070 °F). In the process of smelting, huge amounts of electricity are consumed, making production very expensive in countries where power costs are high.

The tapping of the material from the furnace takes place intermittently. When enough smelted ferrochrome has accumulated in the furnace hearth.

The tap hole is drilled open and a stream of molten metal and slag rushes down a trough into a chill or ladle. Ferrochrome solidifies in large castings that are crushed for sale or further processed.

Ferrochrome is generally classified by the amount of carbon and chrome it contains.

The vast majority of FeCr produced is "charge chrome" from South Africa, with high carbon being the second largest segment followed by the smaller sectors of low carbon and intermediate carbon material.

Ferrochrome Nitride Powder Related Information

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Ferrovanadium Nitride Powder

Product Name: Ferrovanadium Nitride Powder

| Product | Ferrovanadium Nitride Powder |

| Colour | Greyish silver |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | FeVN |

| Product Code | NCZ-CN-149/20 |

| CAS Number | 7439-89-6 / 24646-85-3 |

Ferrovanadium Nitride Powder Description:

Ferrovanadium Nitride (Vanadium-Nitrogen alloy) is a composition ferrovanadium nitride. Ferrovanadium nitride is proposed for joint nitrogen and vanadium steel doping. Ferrovanadium Nitride (Vanadium-Nitrogen Alloy) is a new type of alloy additive, It can substitute Ferro Vanadium used in the production of Micro alloying-steel.Ferrovanadium Nitride Powder Application:

- FeVN alloy powder can be used for structural steel, tool steel, pipeline steel, steel, and cast iron.

- It is used for nitrogen-containing steel melting: high- strength low-alloy steel (HSLA), rail steel, quick cutting steel, etc.

- Ferrovanadium Nitride adding to the steel can increase the strength, tough, tactility, anti-thermal fatigue, etc.

- It also can make the steel be able to fulfill solderability to attain the same strength, adding Ferrovanadium Nitride could save 30-40% of Vanadium, thereby saving the cost.

Ferrovanadium Nitride Powder Advantages:

- Low melting point, high-density products, under the condition of the same production, vanadium and nitrogen yield is higher than similar products.

- Low nitrogen vanadium than more reasonable, high strengthening ability.

- Stable high product purity, ingredients, production has smaller fluctuation, the mechanical performance of steel performance has higher reliability.

Niobium Boride Powder

Niobium Boride Powder

Product Name: Niobium Boride Powder

| MF: | NbB |

| Chemical Name | Niobium Boride Powder |

| EINECS: | 235-723-2 |

| Purity: | 99.9% |

| Molecular weight: | 103.72 |

| Product Number: | NCZ-SC-112/20 |

| Cas Number: | 12619-90-8 |

| Density | 7.39g/ml |

Niobium Boride Powder Related Information

Niobium boride powders having NbB, NbB2 and Nb3B4 phases in various amounts and single phase NbB powders were successfully synthesized by using powder metallurgy methods from related metal oxide raw materials in the presence of a strong reducing agent. Nb2O5, B2O3 and Mg powder blends were milled at room temperature

A high-energy ball mill for different time. Subsequently, an undesired MgO phase was removed from the milled powders by HCl leaching to constitute NbB–NbB2–Nb3B4 as final products, and they were subjected to an annealing process at 1500 °C for 4 h to observe probable boride transformation. Characterization was carried out by XRD, DSC, PSA, SEM/EDX, TEM, and VSM. The effects of milling time (up to 9 h) on the formation, microstructure, and thermal behavior of the final products were investigated.

The reduction reaction took place after milling stoichiometric powder blends for 2 h. Nano-sized NbB–NbB2–Nb3B4 powders in high purity were obtained in the absence of any secondary phase and any impurity via mechanochemistry by milling for 5 h and leaching with 4 mol/L HCl. After annealing, pure and nano-sized NbB–NbB2–Nb3B4 powders transformed into a single NbB phase without leaving behind NbB2 and Nb3B4 phases.

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Silicon Carbide Powder

Product Name: Silicon Carbide Powder

| Product | Silicon Carbide Powder |

| Colour | Black Powder |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | SiC |

| Product Code | NCZ-C-104/20 |

| CAS Number | 409-21-2 |

Silicon Carbide Powder Description:

Silicon carbide is produced in the same way as Black silicon Carbide except for some differences in the raw material. Its crystallization has higher purity and hardness. Green silicon carbide is suitable for processing hard alloy, metallic and non-metallic materials with hard and brittle features such as copper, brass, Aluminum, magnesium, jewel, optical glass, ceramics, etc.

Silicon Carbide Applications:

- One of the best properties of silicon carbide is that it is resistant to alkali and acids.

- It retains strength when applied at high temperatures.

- It shows good electrical conductivity and shock resistance capacity and for this reason, it is preferred for applying in an electric furnace to heat elements.

- It is compatible to apply under extreme conditions of applications.

- Apart from that, this chemical component also shows considerable thermal expansion and conductivity.

- It is an ideal component for applications requiring good flexural strength.

- We provide this product after evaluating the properties, ingredients, and applicability to cover a wide range of industrial usages.

Advantages:

- Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity, and fewer impurities.

- Beckman coulter particle size distribution instrument.

- The laboratory is registered at the government Import and Export Inspection Bureau.

Silicon Carbide Powder Related Information

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Tantalum carbide Powder

Product Name: Tantalum Carbide Powder

| Product | Tantalum Carbide Powder |

| Colour | Brown-Gray |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | TaC |

| Product Code | NCZ-C-105/20 |

| CAS Number | 12070-06-3 |

Tantalum carbide Powder Description:

Tantalum carbides form a family of binary chemical compounds of tantalum and carbon with the empirical formula TaCx, where usually varies between 0.4 and 1. They are extremely hard, brittle, refractory ceramic materials with metallic electrical conductivity. They appear as brown-Gray powders, which are usually processed by sintering. Being important cermet materials, tantalum carbides are commercially used in tool bits for cutting applications and are sometimes added to tungsten carbide alloys.Properties of TaC Tantalum carbide powder:

Tantalum carbides have metallic electrical conductivity, both in terms of its magnitude and temperature dependence. TaC is a superconductor with a relatively high transition temperature of TC = 10.35 K. Application of TaC Tantalum carbide powder- Widely used in the production of microwave absorbing materials, metal powder injection

- Used as all kinds of superhard material and powder metallurgy products additives etc.

- Used as a cutting tool.

- Used for delicate Ceramics.

- Hard wear-resistant alloy tools, tools, molds, and wear-resistant corrosion-resistant structural components additive, improve the toughness of the alloy.

- Tantalum carbide sintered shown in gold, watches can be made decorations.

Reviews

There are no reviews yet.