Iron Boride Powder

₹0.00

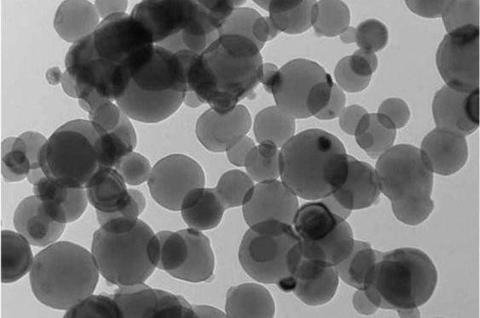

Product Name: Iron Boride Powder

| MF: | Tr-FeB |

| Chemical Name | Iron Boride Powder |

| Color | Grey Powder |

| EINECS Number: | 234-489-9 |

| Purity: | 99.9% |

| Density | ~7 g/cm3 |

| Product Number: | NCZ-NIB-112/20 |

| Cas Number: | 12006-84-8 |

RELATED INFORMATION

Boriding is often used to improve abrasion resistance, corrosion resistance, wear resistance, and oxidation resistance. It is used in oil and gas refinery, chemical extraction, automotive agricultural, stamping, textile extrusion, and injection molding industries. Iron-based coatings recently gained attention for their mechanical, frictional, and corrosion-resistant properties. As compared to the ceramic or cermet type of materials people have used before, iron-based materials are relatively inexpensive, less strategic, and can be produced economically by various thermal methods with ease of fabrication and machining.

Please email us for the customization.

Email: contact@nanochemazone.com

Please contact us for customization and price inquiry

Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.

Note: For pricing & ordering information, please contact us at sales@nanochemazone.com

Please contact us for quotes on Larger Quantities & Customization. E-mail: contact@nanochemazone.com

Customization:

If you are planning to order large quantities for your industrial and academic needs, please note that customization of parameters (such as size, length, purity, functionalities, etc.) are available upon request.

You must be logged in to post a review.

Related products

Aluminum Powder

Aluminum Powder

Product Name: Al Powder

| Product | Al Powder |

| CAS No. | 7429-90-5 |

| Appearance | Grey |

| Purity | 99.9% |

| APS | 1 – 5 Micron (Can be customized) |

| Ingredient | Al+3 |

| Product Code | NCZ-NSC-163/20 |

Description of Al (Aluminum Powder)

| 3D printing metal Powder Powder metallurgy, injection molding, spray painting, etc. |

Al Powder Related Information

Storage Conditions:

Airtight sealed, avoid light, and keep dry at room temperature. Please email us for the customization. Email: contact@nanochemazone.comCoCrW Alloy Powder

Product Name: CoCrW Alloy Powder

| Product |

CoCrW Alloy Powder |

| CAS No. | 7440-50-8/7440-47-3 |

| Appearance | Grey |

| Purity | 99.9% |

| APS | 1 – 5 Microns (Can be customized) |

| Ingredient | CoCrW |

| Product Code | NCZ-NSC-164/20 |

Description:

| 3D printing metal Powder Powder metallurgy(PM), injection molding(MIM), spray painting(SP) etc. |

Ferrovanadium Nitride Powder

Product Name: Ferrovanadium Nitride Powder

| Product | Ferrovanadium Nitride Powder |

| Colour | Greyish silver |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | FeVN |

| Product Code | NCZ-CN-149/20 |

| CAS Number | 7439-89-6 / 24646-85-3 |

Ferrovanadium Nitride Powder Description:

Ferrovanadium Nitride (Vanadium-Nitrogen alloy) is a composition ferrovanadium nitride. Ferrovanadium nitride is proposed for joint nitrogen and vanadium steel doping. Ferrovanadium Nitride (Vanadium-Nitrogen Alloy) is a new type of alloy additive, It can substitute Ferro Vanadium used in the production of Micro alloying-steel.Ferrovanadium Nitride Powder Application:

- FeVN alloy powder can be used for structural steel, tool steel, pipeline steel, steel, and cast iron.

- It is used for nitrogen-containing steel melting: high- strength low-alloy steel (HSLA), rail steel, quick cutting steel, etc.

- Ferrovanadium Nitride adding to the steel can increase the strength, tough, tactility, anti-thermal fatigue, etc.

- It also can make the steel be able to fulfill solderability to attain the same strength, adding Ferrovanadium Nitride could save 30-40% of Vanadium, thereby saving the cost.

Ferrovanadium Nitride Powder Advantages:

- Low melting point, high-density products, under the condition of the same production, vanadium and nitrogen yield is higher than similar products.

- Low nitrogen vanadium than more reasonable, high strengthening ability.

- Stable high product purity, ingredients, production has smaller fluctuation, the mechanical performance of steel performance has higher reliability.

Iron Boride Powder

Product Name: Iron Boride Powder

| MF: | Tr-FeB |

| Chemical Name | Iron Boride Powder |

| Color | Grey Powder |

| EINECS Number: | 234-489-9 |

| Purity: | 99.9% |

| Density | ~7 g/cm3 |

| Product Number: | NCZ-NIB-112/20 |

| Cas Number: | 12006-84-8 |

Iron Boride Powder Description

Iron Boride Powder is often used to improve abrasion resistance, corrosion resistance, wear resistance, and oxidation resistance. It is used in oil and gas refinery, chemical extraction, automotive agricultural, stamping, textile extrusion, and injection molding industries. Iron-based coatings recently gained attention for their mechanical, frictional, and corrosion-resistant properties. As compared to the ceramic or cermet type of materials people have used before, iron-based materials are relatively inexpensive, less strategic, and can be produced economically by various thermal methods with ease of fabrication and machining.

Iron Boride Powder Related Information

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Manganese Nitride Powder

Manganese Nitride Powder

Product Name: Manganese Nitride Powder

| Product | Manganese Nitride Powder |

| Colour | Dark Gray |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | MnN |

| Product Code | NCZ-CN-148/20 |

| CAS Number | 7439-96-5 |

Manganese Nitride Powder Description:

Manganese Nitride Powder is generally immediately available in most volumes. High purity, submicron and nanopowder forms may be considered. Our factory produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade

Manganese Nitride in Briquettes, as a kind of Nitrogen and manganese alloy additive, its characteristics are: high content of main elements, low content of harmful impurities, Nitrogen utilization is to be improved after add melt. We adopt the continuous nitride process with unique intellectual property rights in mass production, which has stable quality and uniform nitrogen

Manganese Nitride Powder Application:

- Used for production of special alloy steel, high strength steel, stainless steel, heat-resistant steel products

2. Application in the field of high nitrogen steel smelting

- Used as the steel-making additive and endow many excellent performances to steel grade such as strength, toughness, creep resistance, etc.

- Specialty demonstrated its good market prospects in large diameter steel pipe of transmitting oil and gas strength steel in shipbuilding and automotive.

Basic information of Manganese Nitride Powder

Manganese (atomic symbol: Mn, atomic number: 25) is a Block D, Group 7, Period 4 element with an atomic weight of 54.938045.

In its elemental form, manganese has a silvery metallic appearance.

It is a paramagnetic metal that oxidizes easily in addition to being very hard and brittle.

Manganese is found as a free element in nature and also in the minerals pyrolusite, braunite, psilomelane, and rhodochrosite.

Nitrogen is a Block P, Group 15, Period 2 element.

Nitrogen is an odorless, tasteless, colorless, and mostly inert gas.

It is the seventh most abundant element in the universe, and it constitutes 78.09% (by volume) of Earth’s atmosphere.

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Silicon Carbide Powder

Product Name: Silicon Carbide Powder

| Product | Silicon Carbide Powder |

| Colour | Black Powder |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | SiC |

| Product Code | NCZ-C-104/20 |

| CAS Number | 409-21-2 |

Silicon Carbide Powder Description:

Silicon carbide is produced in the same way as Black silicon Carbide except for some differences in the raw material. Its crystallization has higher purity and hardness. Green silicon carbide is suitable for processing hard alloy, metallic and non-metallic materials with hard and brittle features such as copper, brass, Aluminum, magnesium, jewel, optical glass, ceramics, etc.

Silicon Carbide Applications:

- One of the best properties of silicon carbide is that it is resistant to alkali and acids.

- It retains strength when applied at high temperatures.

- It shows good electrical conductivity and shock resistance capacity and for this reason, it is preferred for applying in an electric furnace to heat elements.

- It is compatible to apply under extreme conditions of applications.

- Apart from that, this chemical component also shows considerable thermal expansion and conductivity.

- It is an ideal component for applications requiring good flexural strength.

- We provide this product after evaluating the properties, ingredients, and applicability to cover a wide range of industrial usages.

Advantages:

- Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity, and fewer impurities.

- Beckman coulter particle size distribution instrument.

- The laboratory is registered at the government Import and Export Inspection Bureau.

Silicon Carbide Powder Related Information

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Tantalum boride Powder

Product Name: Tantalum boride Powder

| MF: | TaB |

| Chemical Name |

Tantalum boride Powder |

| Color | Gray |

| EINECS | 234-496-7 |

| Purity: | 99.9% |

| Molecular weight: | 191.76 |

| Product Number: | NCZ-SC-116/20 |

| Cas Number: | 12045-19-1 |

| Density: | 14.2 g/cm3 |

Tantalum boride Powder RELATED INFORMATION

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Tungsten Carbide Powder

Tungsten Carbide Powder

Product Name: Tungsten Carbide Powder

| Product | Tungsten Carbide Powder |

| Colour | Grey |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | WC |

| Product Code | NCZ-C-109/20 |

| CAS Number | 12070-12-1 |

Brief Description of WC Tungsten Carbide Powder

Tungsten carbide powder (chemical formula: WC ) is a chemical compound (specifically, a carbide ) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine Gray powder, but it can be pressed and formed into shapes for use in industrial machinery, cutting tools, abrasives, armor-piercing rounds, other tools and instruments, and jewelry. Physical Properties of WC Tungsten Carbide Powder Tungsten carbide has a high melting point at 2,870 °C (5,200 °F), a boiling point of 6,000 °C (10,830 °F) when under a pressure equivalent to 1 standard atmosphere (100 kPa), the thermal conductivity of 110 W·m−1·K−1, and a coefficient of thermal expansion of 5.5 µm·m−1·K−1. Tungsten carbide is extremely hard, ranking about 9 on Mohs scale, and with a Vickers number of around 2600. It has Young’s modulus of approximately 530–700 GPa, a bulk modulus of 630–655 GPa, and a shear modulus of 274 GPa. It has an ultimate tensile strength of 344 MPa, the ultimate compression strength of about 2.7 GPa and a Poisson’s ratio of 0.31. Chemical Properties of WC Tungsten Carbide Powder There are two well-characterized compounds of tungsten and carbon, WC and tungsten semi abide, W2C. Both compounds may be present in coatings and the proportions can depend on the coating method. At high temperatures, WC decomposes to tungsten and carbon and this can occur during high-temperature thermal spray, e.g., in high-velocity oxygen fuel (HVOF) and high energy plasma (HEP) methods.Application of WC Tungsten Carbide Powder

1 Used for Producing high capability nano-crystalline or superfine horniness alloy, hard-face abrasion-resistant spraying and petrochemical cracking catalyst;- Used for chipless forming tools; Cutting tools; Mining tolls; Nano-composites (for enhanced hardness, strength, and wear resistance);

- Used for erosion-resistant coatings; wear-resistance coatings; Corrosion-resistant coatings; Wear-resistant parts

- To produce hard carbide.

Reviews

There are no reviews yet.