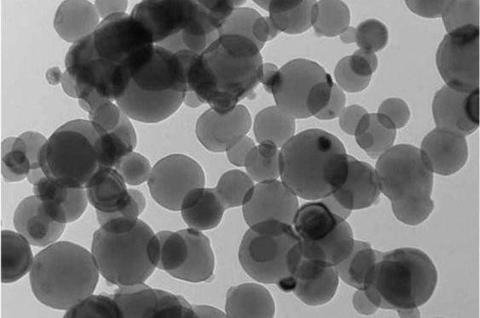

Iron Boride Powder

₹0.00

Product Name: Iron Boride Powder

| MF: | Tr-FeB |

| Chemical Name | Iron Boride Powder |

| Color | Grey Powder |

| EINECS Number: | 234-489-9 |

| Purity: | 99.9% |

| Density | ~7 g/cm3 |

| Product Number: | NCZ-NIB-112/20 |

| Cas Number: | 12006-84-8 |

Iron Boride Powder Description

Iron Boride Powder is often used to improve abrasion resistance, corrosion resistance, wear resistance, and oxidation resistance. It is used in oil and gas refinery, chemical extraction, automotive agricultural, stamping, textile extrusion, and injection molding industries. Iron-based coatings recently gained attention for their mechanical, frictional, and corrosion-resistant properties. As compared to the ceramic or cermet type of materials people have used before, iron-based materials are relatively inexpensive, less strategic, and can be produced economically by various thermal methods with ease of fabrication and machining.

Iron Boride Powder Related Information

Please email us for the customization.

Email: contact@nanochemazone.com

Please contact us for customization and price inquiry

Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.

Note: For pricing & ordering information, please contact us at sales@nanochemazone.com

Please contact us for quotes on Larger Quantities & Customization. E-mail: contact@nanochemazone.com

Customization:

If you are planning to order large quantities for your industrial and academic needs, please note that customization of parameters (such as size, length, purity, functionalities, etc.) are available upon request.

You must be logged in to post a review.

Related products

Aluminum Powder

Aluminum Powder

Product Name: Al Powder

| Product | Al Powder |

| CAS No. | 7429-90-5 |

| Appearance | Grey |

| Purity | 99.9% |

| APS | 1 – 5 Micron (Can be customized) |

| Ingredient | Al+3 |

| Product Code | NCZ-NSC-163/20 |

Description of Al (Aluminum Powder)

| 3D printing metal Powder Powder metallurgy, injection molding, spray painting, etc. |

Al Powder Related Information

Storage Conditions:

Airtight sealed, avoid light, and keep dry at room temperature. Please email us for the customization. Email: contact@nanochemazone.comChromium Diboride Powder

Chromium Diboride Powder

Product Name: Chromium Diboride Powder

| MF: | CrB2 |

| Chemical Name |

Chromium Diboride Powder |

| Appearance | silver, ceramic material |

| EINECS | 234-499-3 |

| Purity: | 99.9% |

| Density: | 5.20 g/cm3 |

| Product Number: | NCZ-NCD-117/20 |

| Cas Number: | 12007-16-8 |

Ferro Titanium Carbide Powder

Product Name: Ferro Titanium Carbide Powder

| Product | Ferro Titanium Carbide Powder |

| Colour | Gray Powder |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | FeTiC |

| Product Code | NCZ-C-102/20 |

| CAS Number | 12604-56-7 |

Application of Ferro Titanium carbide powder:

In the present study, Fe-based hardfacing coating reinforced by TiC particles was obtained by manual shielded metal arc welding (SMAW) in which H08A bare electrode was coated with fluxes, to which different measures of ferrotitanium, rutile, graphite, calcium carbonate, and calcium fluoride had been added.

The microstructure and wear properties of the hardfacing coating were studied through scanning electron microscopy (SEM), transmission electron microscopy (TEM), an X-ray diffractometer (XRD), and a wear test.

The results indicate that TiC particles are produced by a direct metallurgical reaction between ferrotitanium and graphite during welding.

TiC particles are uniformly dispersed in the matrix of lath martensite and retained austenite with particle sizes in the range of 3–5 μm. Fe-based hardfacing coating reinforced by TiC particles is found to possess better wear resistance and a lower coefficient of friction than that of the AISI 1045 steel substrate.

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Ferrochrome Nitride Powder

| Product | Ferrochrome Nitride Powder |

| Colour | Black |

| Purity | ≥ 99.9% |

| Particle size | 1-10 µM (customizable) |

| Ingredient/MF | FeCrN |

| Product Code | NCZ-CN-151/20 |

| CAS Number | 7439-89-6, / 24094-93-7 |

- Widely used in stainless steel, heat resistant steel, corrosion-resistant steel, alloy steel, and other special steel smelting production

- Used in steelmaking industrial, casting foundry

Molybdenum Boride Powder

Molybdenum Boride Powder

Product Name: Molybdenum Boride Powder

| MF: | Tr-MoB2 |

| Chemical Name | Boride Powder |

| Color | Yellow Gray |

| EINECS No.: | 234-502-8 |

| Purity: | 99.9% |

| Density: | 9.26 g/ cm3 |

| Product Number: | NCZ-NMB-112/20 |

| Cas Number: | 12006-99-4 |

RELATED INFORMATION

It's mainly used as an additive of electronic tungsten, molybdenum alloy, etc., and can also be used in the manufacture of wear semiconductor thin film and coating materials. Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Niobium Boride Powder

Niobium Boride Powder

Product Name: Niobium Boride Powder

| MF | NbB |

| Chemical Name | Niobium Boride Powder |

| EINECS | 235-723-2 |

| Purity | 99.9% |

| Molecular weight | 103.72 |

| Product Number | NCZ-SC-112/20 |

| Cas Number | 12007-29-3 |

| Density | 7.39g/ml |

Niobium Boride Powder

Niobium boride Powders having NbB, NbB2, and Nb3B4 phases in various amounts and single-phase NbB powders were successfully synthesized by using powder metallurgy methods from related metal oxide raw materials in the presence of a strong reducing agent. Nb2O5, B2O3, and Mg powder blends were milled at room temperature by a high-energy ball mill for a different time. Subsequently, an undesired MgO phase was removed from the milled powders by HCl leaching to constitute NbB–NbB2–Nb3B4 as final products, and they were subjected to an annealing process at 1500 °C for 4 h to observe probable boride transformation. Characterization was carried out by XRD, DSC, PSA, SEM/EDX, TEM, and VSM.

The effects of milling time (up to 9 h) on the formation, microstructure, and thermal behavior of the final products were investigated. The reduction reaction took place after milling stoichiometric powder blends for 2 h. Nano-sized NbB–NbB2–Nb3B4 powders in high purity were obtained in the absence of any secondary phase and any impurity via mechanochemistry by milling for 5 h and leaching with 4 mol/L HCl. After annealing, pure and nano-sized NbB–NbB2–Nb3B4 powders transformed to a single NbB phase without leaving behind NbB2 and Nb3B4 phases.

RELATED INFORMATION Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Niobium Boride Powder

Niobium Boride Powder

Product Name: Niobium Boride Powder

| MF: | NbB |

| Chemical Name | Niobium Boride Powder |

| EINECS: | 235-723-2 |

| Purity: | 99.9% |

| Molecular weight: | 103.72 |

| Product Number: | NCZ-SC-112/20 |

| Cas Number: | 12619-90-8 |

| Density | 7.39g/ml |

Niobium Boride Powder Related Information

Niobium boride powders having NbB, NbB2 and Nb3B4 phases in various amounts and single phase NbB powders were successfully synthesized by using powder metallurgy methods from related metal oxide raw materials in the presence of a strong reducing agent. Nb2O5, B2O3 and Mg powder blends were milled at room temperature

A high-energy ball mill for different time. Subsequently, an undesired MgO phase was removed from the milled powders by HCl leaching to constitute NbB–NbB2–Nb3B4 as final products, and they were subjected to an annealing process at 1500 °C for 4 h to observe probable boride transformation. Characterization was carried out by XRD, DSC, PSA, SEM/EDX, TEM, and VSM. The effects of milling time (up to 9 h) on the formation, microstructure, and thermal behavior of the final products were investigated.

The reduction reaction took place after milling stoichiometric powder blends for 2 h. Nano-sized NbB–NbB2–Nb3B4 powders in high purity were obtained in the absence of any secondary phase and any impurity via mechanochemistry by milling for 5 h and leaching with 4 mol/L HCl. After annealing, pure and nano-sized NbB–NbB2–Nb3B4 powders transformed into a single NbB phase without leaving behind NbB2 and Nb3B4 phases.

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Tantalum boride Powder

Product Name: Tantalum boride Powder

| MF: | TaB |

| Chemical Name |

Tantalum boride Powder |

| Color | Gray |

| EINECS | 234-496-7 |

| Purity: | 99.9% |

| Molecular weight: | 191.76 |

| Product Number: | NCZ-SC-116/20 |

| Cas Number: | 12045-19-1 |

| Density: | 14.2 g/cm3 |

Reviews

There are no reviews yet.