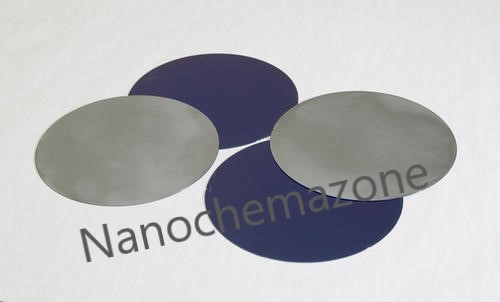

Single Crystal Silicon-Silicon dioxide Wafer

₹0.00

Single Crystal silicon-silicon dioxide Wafer

Product Name: Single Crystal silicon-silicon dioxide Wafer

| Product Name | Single Crystal silicon-silicon dioxide Wafer P-type (4 inches) |

| Cat No. | NCZ-NSC318/20 |

| Día | 100 mm (4 inches) |

| Orientation | <100> |

| Wafer thickness | 500 micrometer |

| Resistivity | <0.01 |

| Polished | Front Side Polished |

| Thickness | 300 nm (dry) |

| Purity | 99.9% |

| Formula | Si/SiO2 |

Single Crystal silicon-silicon dioxide Wafer P-type Description :

Provided in a single wafer case

Silicon oxide wafer SIO2 thin-film among semiconductor technology, SiO2 thin film layers are mainly used as dielectric material and more recently, they are integrated with MEMS (Micro Electro Mechanical Systems) devices. The simplest way to produce silicon oxide layers on silicon wafers is to oxidize silicon with oxygen.

Single Crystal silicon-silicon dioxide Wafer RELATED INFORMATION

Storage Conditions:

Airtight sealed, avoid light and keep dry at room temperature.

Please email us for the customization.

Email: contact@nanochemazone.com

Note: We supply different size ranges of nano and micron size powder as per the client’s requirements and also accept customization in various parameters.

Note: For pricing & ordering information, please contact us at sales@nanochemazone.com

Please contact us for quotes on Larger Quantities & Customization. E-mail: contact@nanochemazone.com

Customization:

If you are planning to order large quantities for your industrial and academic needs, please note that customization of parameters (such as size, length, purity, functionalities, etc.) are available upon request.

You must be logged in to post a review.

Related products

Calcium Magnesium Silicate

Calcium Magnesium Silicate

| Product |

Calcium Magnesium Silicate |

| CAS No. | N/A |

| Appearance | White |

| Purity | 99% |

| APS | 1-5µM (Can be customized) |

| Ingredient | CaMgSi2O6:Eu(2+) |

| Product Code | NCZ-NSC614/20 |

| Molecular Weight | 156.47 g/mol |

| Density | 2.9 g/cm3 |

| Melting Point | 2,130 °C (3,870 °F; 2,400 K) |

Calcium Magnesium Silicate Description

Calcium Chromate is generally immediately available in most volumes. Hydrate or anhydrous forms may be purchased. High purity, submicron and nanopowder forms may be considered. Nanochemazone produces to many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information is available as is a Reference Calculator for converting relevant units of measurement.

Related Information

Storage Conditions:

Airtight sealed, avoid light and keep dry at room temperature.

Please contact us for customization and price inquiry

Email: contact@nanochemazone.com

Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.

Pinnatoxin-G CAS: 1312711-74-2

Pinnatoxin-G

| Product Name | Pinnatoxin-G |

| Cat No | NCZ-000-101 |

| CAS No | 1312711-74-2 |

| Synonyms | Pinnatoxin G |

| Molecular Formula | C42H63NO7 |

| Molecular Weight | 693.95 |

Pinnatoxin-G CAS: 1312711-74-2

D3O 10 mm Solid Sheet 10″x14.5″ (AERO) UnskivedSilicon oxide wafer P-Type (2 inch)

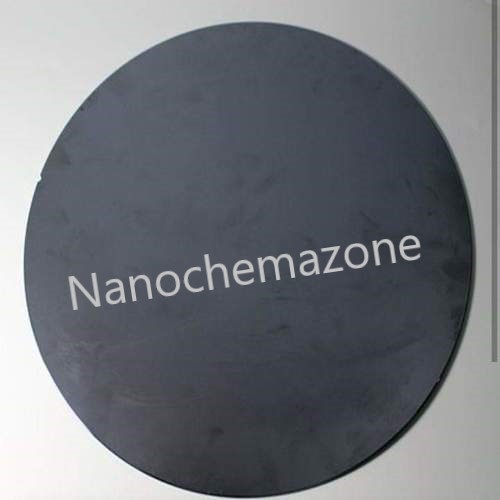

Product Name: Silicon oxide wafer P-Type (2 inches)

| Product Name | Silicon oxide wafer P-Type (2 inches) |

| Cat. No. | NCZ-NSC318/20 |

| Diameter | 50.8+- 0.2 mm (2 inch) |

| Oxide Thickness | 300 +- 20 nm (dry) |

| Resistivity | (1-10 Ohm/sq). |

| Thickness | 300+ 15 µm |

| Orientation | <100>+- 0.5 |

Silicon oxide wafer P-Type (2 inches) Description

Provided in Single wafer caseSingle Crystal Silicon for solar energy applications includes p-type and n-type silicon. Silicon Silicon-based photovoltaic cells (PV Cells) for solar energy are fabricated from a positively charged or p-type silicon layer underneath a negatively charged or n-type silicon layer. These layers can be produced from single crystal silicon material sold under the AE Solar Energy group. Most silicon-based PV solar cells are produced from polycrystalline silicon with single-crystal systems the next most common. Silicon Metal is also available as a polycrystalline powder for casting, amorphous silicon for deposition, disc, granules, ingot, pellets, pieces, powder, rod, sputtering target, wire, and other forms and custom shapes. Ultra-high purity and high purity forms also include submicron powder and nanoscale powder. Single Crystal Silicon is generally immediately available in most volumes.

Silicon oxide wafer P-Type (2 inches) RELATED INFORMATION

Storage Conditions: Airtight sealed, avoid light, and keep dry at room temperature. Please email us for the customization. Email: contact@nanochemazone.com Note: We supply different size ranges of nano and micron size powder as per the client’s requirements and also accept customization in various parameters.Single Crystal Silicon Wafer Diameter Intrinsic (4-inch)

Single Crystal Silicon Wafer Diameter Intrinsic (4-inch)

Product Name: Single Crystal Silicon Wafer Diameter Intrinsic (4-inch)

| Product Name | Single Crystal Silicon Wafer |

| Cat No. | NCZ-NSC327/20 |

| Diameter | 4 inches |

| Doping | undoped |

| Thickness | 400~415+/-10um |

| Resistivity | 4000 5000 ohms.cm Undoped |

| Orientation | <100>+/-0.5 |

| Polishing | one side polished |

| Application | Research Material |

| Thickness | 525 Micron |

| Resistivity | 1-10 ohm-cm |

| Polished | Single side polished |

Single Crystal Silicon Wafer thickness Is determined by the mechanical strength of the material used the wafer must be thick enough to support its own weight without cracking during handling. Wafers are grown from crystal having a regular crystal structure, with silicon having a diamond cubic structure. Orientation is defined by the Miller index with (100) or (111) faces being the most common for silicon. Ion implantation depends on the wafer’s crystal orientation since each direction offers distinct paths the transport.

Note: SSP = Single Side Polished, DSP = Double Side Polished, E = Etched, C = AsCut, Material - CZ unless noted, L = Lapped, Und = Undoped (Intrinsic)Single crystal silicon wafer Intrinsic (2-inch)

Single crystal silicon wafer Intrinsic (2-inch)

Product Name: Single crystal silicon wafer Intrinsic (2-inch)

| Product Name | Single crystal silicon wafer Intrinsic (2-inch) |

| Cat No. | NCZ-NSC329/20 |

| Diameter | 2 inch |

| Doping | Intrinsic |

| Resistivity | (>1000ohm/sq.) |

| Thickness | 400µm |

| Orientation | 100 |

| Polished | Single side polished |

Single crystal silicon wafer Intrinsic (2-inch) is the most widely used semiconductor material as a substrate material due to its excellent machinability, mechanical stability, and the potential to combine sensing elements and electronics on the same substrate. Circular wafers made of silicon are used as a substrate in most MEMS sensors.

The crystal orientation should be known before manufacturing since silicon has orientation-dependent properties such as piezoresistivity coefficients and etching rates. The common orientation is (100) where the numbers represent Miller indices.

As an example, (100) wafer that has a primary flat side as an indication of < 110 > direction. When a piezoresistive element is placed on a (100) wafer, the orientation should be parallel to < 110 > direction if the piezoresistivity coefficients in that direction are intended to be utilized.

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in the various parameters.Single Crystal Silicon Wafer N-Type

Single Crystal Silicon Wafer N-Type (1 inch)

Product Name: Single Crystal Silicon Wafer N-Type (1 inch)

| Product Name | Single Crystal Silicon Wafer N-Type (1 inch) |

| Cat No. | NCZ-NSC330/20 |

| Size | 1 inch |

| Thickness | 300-380 micro-meter |

| Type | N-type |

| Dopant | Phosphorus |

| Resistivity | 1-10 ohm/cm |

| Surface | Single side polished |

| Boling Point | 2355 °C (lit.) |

| Melting Point | 1240 °C,1410 °C (lit.) |

| Density | 2.33 g/mL at 25 °C (lit.) |

| Semiconductor Properties | <100>, N-type |

| SMILES string | [Si] |

Single Crystal Silicon Wafer N-Type (1 inch). We have heated polished doped single-crystal silicon wafers in a single-mode microwave cavity to temperatures where surface to surface bonding occurred. The absorption of microwaves and heating of the wafers is attributed to the inclusion of n-type or p-type impurities into these substrates.

A cylindrical cavity TM (sub 010) standing wave mode was used to irradiate samples of various geometry at positions of high magnetic field. This process was conducted in a vacuum to exclude plasma effects.

This initial study suggests that the inclusion of impurities in single crystal silicon significantly improved its microwave absorption (loss factor) to a point where heating silicon wafers directly can be accomplished in minimal time. Bonding of these substrates, however, occurs only at points of intimate surface to surface contact. The inclusion of a thin metallic layer on the surfaces enhances the bonding process.

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in the various parametersSingle Crystal Silicon Wafer N-type (4-inch)

Single Crystal Silicon Wafer N-type (4-inch)

Product Name: Single Crystal Silicon Wafer N-type (4-inch)

| Product Name | Single Crystal Silicon Wafer N-type (4-inch) |

| Cat No. | NCZ-NSC331/20 |

| Día | 4 inches |

| Type | N |

| Diameter (mm) | 4” (100.8mm) |

| Type | N-Type |

| Doping | Phosphorous |

| Crystal Orientation | <100> |

| Surface: | Single Side Polished |

| Thickness | 250-500μm |

| Resistivity | 1-10ohm-cm |

| Crystal method | CZ |

| RRG (%) | ≤12 |

| Oxygen Contents (ppm) | 12.5-16.5 |

| Carbon Contents (ppm) | ≤1 |

Wafer resizing is sometimes referred to as wafer coring, re-sizing, cut down, cut-down, downsizing, down-sizing, size reducing or size reduction. We can accept orders ranging from a single wafer to hundreds of wafers per month. Our process is efficient, innovative, and ESD friendly. Our proprietary process causes less stress to the silicon wafer than other resizing methods. We also round wafer edges to eliminate edge chipping.

We frequently work with 2” (50 mm), 3” (75 mm), 100 mm (4”), 125 mm (5”), 150 mm (6”), 200 mm (8”), and 300 mm wafers; however, we are also capable of producing custom non-standard sizes.

Please email us for the customization. Email: contact@nanochemazone.com Please contact us for customization and price inquiry Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in the various parameters.Single Crystal Silicon Wafer P-Type (4 Inch)

Single Crystal silicon-silicon dioxide Wafer N-type (4 inch)

| Product Name | Single Crystal Silicon Wafer P-Type (4 Inch) |

| Cat No. | NZC-NSC333/20 |

| MF | Si/SiO2 |

| Día | 100mm ± 0.5mm (4 inch) |

| Type/Dopant | P |

| Orientation | <100> |

| Wafer thickness | 525±25um |

| Resistivity | 1-10 ohm-cm |

| Polished | Single side polished |

| TTV | < 10um |

| SiO2 Oxide Thickness | 300 nm (dry) |

Crystal silicon-silicon dioxide Wafer N-type (4 inches) Description

Single crystal silicon is the most widely used semiconductor material as a substrate material due to its excellent machinability, mechanical stability, and the potential to combine sensing elements and electronics on the same substrate. Circular wafers made of silicon are used as the substrate in most MEMS sensors. The crystal orientation should be known before manufacturing since silicon has orientation-dependent properties such as piezoresistivity coefficients and etching rates. The common orientation is (100) where the numbers represent Miller indices. As an example, (100) wafer that has a primary flat side as an indication of < 110 > direction. When a piezoresistive element is placed on a (100) wafer, the orientation should be parallel to < 110 > direction if the piezoresistivity coefficients in that direction are intended to be utilized.

Note: For pricing & ordering information, please contact us at sales@nanochemazone.com Please contact us for quotes on Larger Quantities & Customization. E-mail: contact@nanochemazone.com Customization: If you are planning to order large quantities for your industrial and academic needs, please note that customization of parameters (such as size, length, purity, functionalities, etc.) are available upon request.

Reviews

There are no reviews yet.